Wagner Pump Repair Keeps Wine Flowing

By . Posted on in Engineering Stories

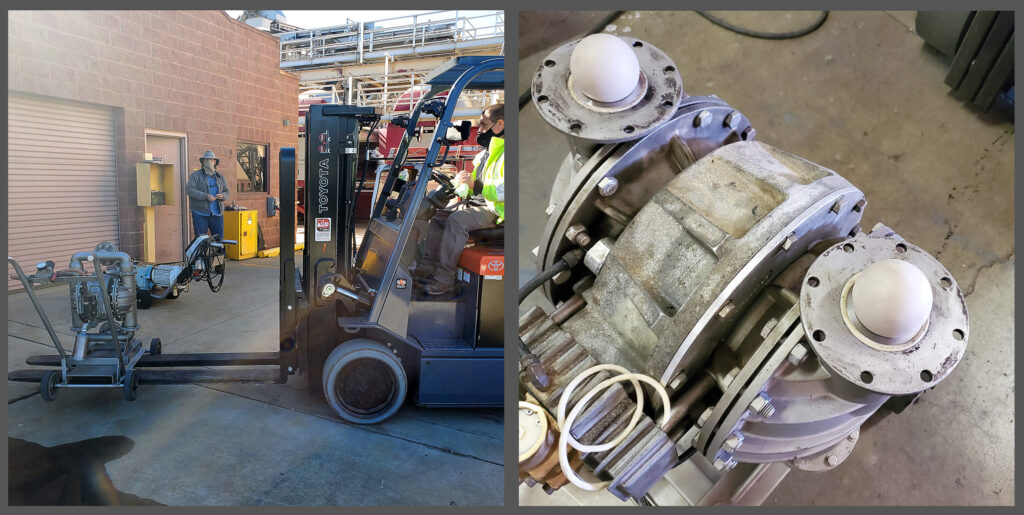

AODD pump at Kendall Jackson vineyard quickly returned to service

With an operation that produces more than five million cases of wine a year, Kendall Jackson’s facilities always need to be running in top form. So when one of their locations, Jackson Family Wines in Soledad, Ca., noticed that a key pump was running sluggishly, they called in the experts at Wagner Process Equipment to troubleshoot the pump.

The underperforming pump was a Wilden H800 high pressure Air Operated Double Diaphragm pump, used to push wine through a Diatomaceous Earth filter press prior to bottling. The H800 is a unique AODD pump in that it can overcome up to 300psi discharge pressure. Most AODD pumps can only overcome 125psi max.

This pressure capability comes with more moving parts and functionality to consider when it comes to pump repair. With deep expertise in servicing all pump types and brands, Wagner was confident in its ability to handle what is considered one of the most complicated and frustrating AODD pumps to work on. Their team replaced all gaskets and seals on the moving parts, disassembled and cleaned key components for an unrestricted air flow path, and reassembled the pump.

“When you consider how much pressure this pump is producing and realize the amount of production that depends on the pump working, it very quickly makes apparent how important this pump is to their operations,” explains Wagner Territory Manager, Andrew Jones. “This kind of pump is critical to the success of the winery. We’re always happy to assist in keeping production going for one of California’s most cherished products.”

The AODD is now back in service and running like a new pump.