Wagner and Gusher Partner on Pumps at High Producing EV Manufacturer

By . Posted on in Engineering Stories

Range of pumps installed at Western US plant that produces nearly a car a minute

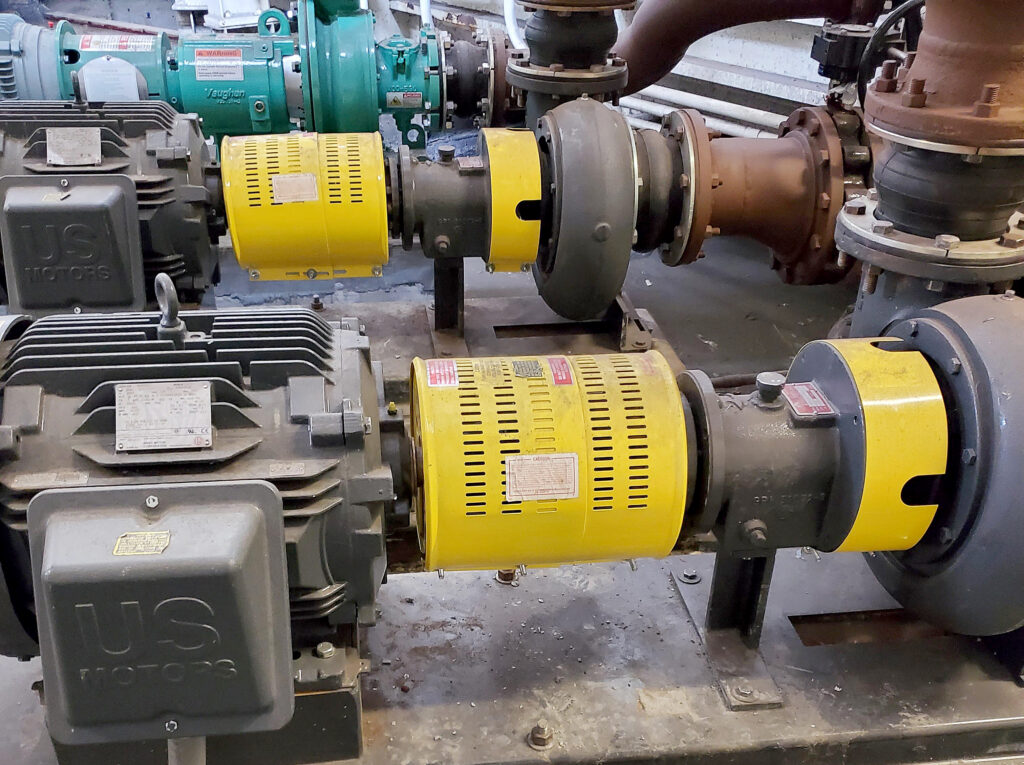

A Western US electric vehicle manufacturing facility that uses a host of Gusher pumps was recently named the highest producing US auto plant of 2021. The account is serviced by Ruthman distributor Wagner Process Equipment. Wagner supports more than 50 Gusher pumps across the plant’s e-coat and paint departments.

The busy plant produced an average of 8,550 vehicles a week last year. With pumps an integral part of the production line, it’s fair to speculate that Gusher’s dependable reliability contributed to consistently high production levels.

The Gusher pumps at the plant span most of the available Gusher product range including vertical and horizontal models from the 7600 Series, ANSI Series, 7550 Series and Self-Priming Series. Some of the pumps have been in service since the 1990’s in older portions of the plant (under a now defunct manufacturing brand) and Wagner is helping them to slowly upgrade non-Gusher pumps across newer portions of the plant.

The installed pumps are moving RO water, degreaser, ecoat, wastewater and paint at capacities ranging from a few hundred gallons per minute up to 1500 gpm. Pumping for these processes requires special considerations in terms of materials, mechanical seals, and temperature, as well as clean barrier fluid supply.

While Gusher’s pumps boast superior service life and reliability, ecoat and automotive paint are particularly harsh applications that can damage even the most durable pumps and seals. The plant also keeps a number of spare pumps on hand to keep production moving in the event that maintenance is required.

And when those maintenance needs come up, Wagner’s Andrew Jones is there to make sure pumps are serviced quickly.

“A lot of the time when I go out to there, I could likely sit behind my desk and work the problem from there,” explains Andrew. “But the maintenance guys and engineers I work with like the face-to-face attention, and the fact that I am willing to jump in with a wrench or gauge and get them back up and running.”

“The plant employs a lot of young engineers. While they have done a ton of work at school to get their degree, the pumping aspect seems to throw a lot of them a loop. They appreciate my expertise and knowledge in this area.”

When asked what makes this manufacturer so successful and productive, Andrew credits their willingness to upgrade and innovate.

He elaborates, “Honestly, one of the coolest things they do is listen to facility improvement suggestions. I can’t tell you how many calls I have gone on at other facilities, suggested certain alterations to the system, and nothing gets done. It is probably one of the biggest reasons that this plant is able to do nearly a car every minute. They see opportunity for improvement and if they believe it will be better for the company then they just go for it.”

Wagner’s knowledge and service and Gusher’s quality have won them the pump business for the company’s new Southwestern US plant. A number of pumps have been supplied over the past year for the new EV facility, which came online in January of 2022.