Just in Time for NFL Draft Ruthman Companies Divisions Collaborate on Detroit Dodge Fountain Project

By . Posted on in Engineering Stories

Distributor Great Lakes Pumps facilitates Process Systems Inc.’s vertical turbine pump refurbishments

The eyes of the sporting world will be on Detroit’s Hart Plaza for the 2024 NFL Draft Experience this Thursday, April 25th. The event will also mark the re-commissioning of the plaza’s centerpiece, the Horace E. Dodge and Son Memorial Fountain. Two Ruthman Companies’ divisions, Great Lakes Pumps and Process Systems Inc. worked together to deliver the vertical turbine pumps that power the fountain’s majestic display.

Designed in 1978 by sculptor Isamu Noguchi, the fountain is considered to be ‘the heart of the Hart’. Four Layne Bowler (Pentair Aurora) vertical turbine pumps power the fountain’s various water features. After falling into disrepair, the features failed one by one, until the entire fountain went dormant over a decade ago.

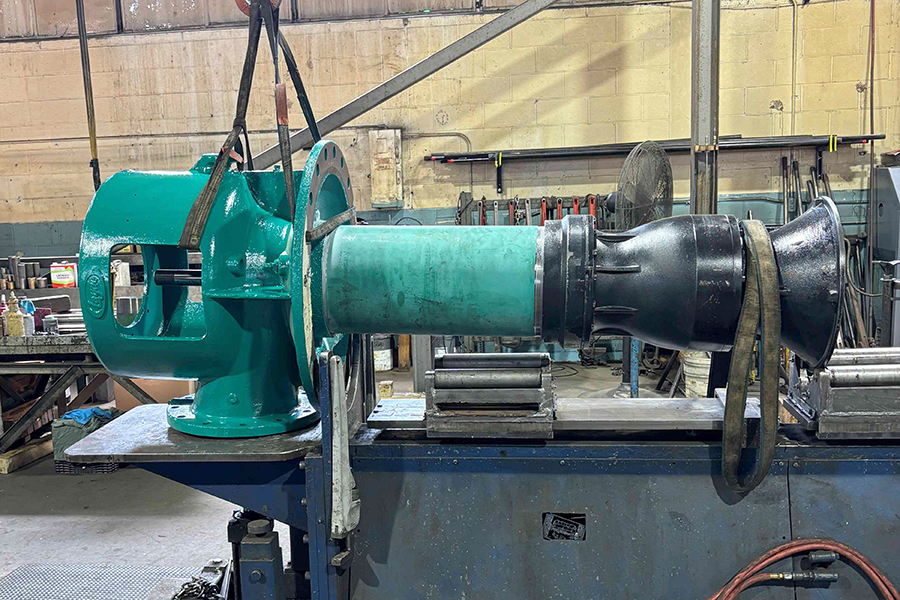

As part of an overall plaza restoration to ready it to host the Draft, PSI remanufactured each pump with all new Process Systems components below the head. The existing head and seal boxes were overhauled and equipped with new seals.

PSI engineers had to precisely mate machined components to the new bowl assemblies and the refurbished Layne discharge heads. This was essential to ensure the final products fit exactly as the old ones did in the existing pump cans. The pump cans were also rehabbed, and both pumps and cans were coated with Scotch Kote 134 for rust protection and longevity.

The capacity of the pumps ranges from 1000 gpm @ 60’ TDH at the low end to 4800 gpm @ 150’ TDH at the high end. There were a number of design considerations unique to this application. Because visitors frequently toss coins and pebbles into the fountain along with their wishes, the pumps had to be designed to handle these smaller solids, in addition to any leaves and outdoor debris that falls in.

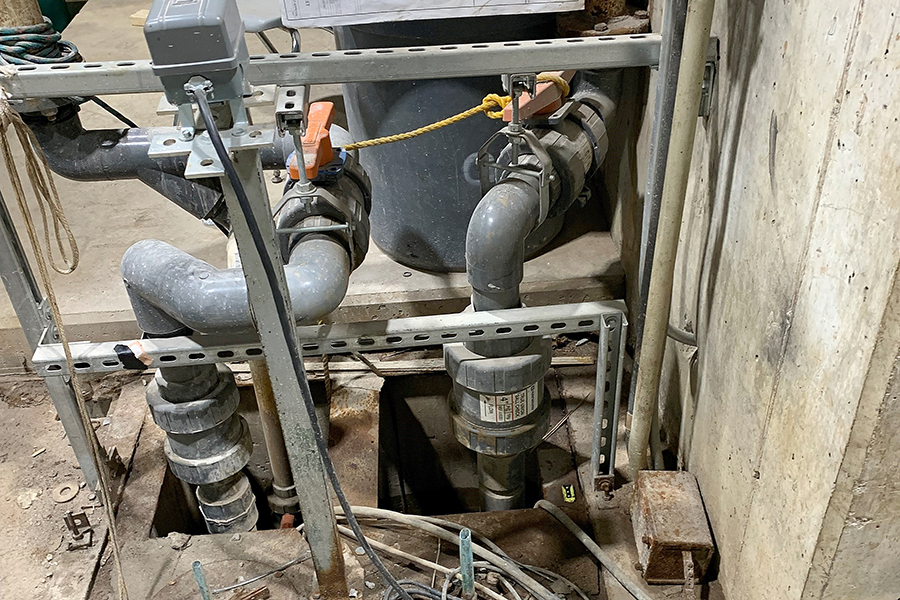

As the previous pumps failed from starvation due to the outside tank mounting arrangement, PSI chose models with low NPSH requirements to accommodate this can mounting arrangement. Finally, due to the low ceiling height in the pump room, the motor shafts were installed before the motors were set, which is not the typical installation procedure.

According to Great Lakes’ Sales Representative Ahmed Udin, one of the biggest challenges on this job was time. With the Draft date set and immovable, the deadline was absolute. “We had less than 3 months to get this job done to be ready in time for the Draft.”

“We received this opportunity after the contractor visited our facility in Warren [MI] and left impressed with our capabilities,” explained PSI General Manager Scott Mezuk. “Knowing the high profile of this project, and that it was part of a literal piece of art, as opposed to an industrial facility, we took a few extra steps for presentation of the pumps for better wear life and lasting overall appearance.”

“It is exciting for Great Lakes Pump and Process Systems to be a part of history at Hart Plaza not only for the NFL Draft this week, but for years to come as families enjoy the fountain,” added Great Lakes’ Outside Sales Representative Ryan Miller. “Scott Mezuk and PSI have been awesome through the whole process as well. Great support and teamwork.”

All four pumps were delivered and installed on time. As the City of Detroit is running just the main water feature (pictured below) for the draft, only the largest capacity pump will be in operation this week. The other aspects of the fountain, powered by the remaining three pumps, will be showcased during the Memorial Day holiday weekend.